So, this one isn’t really a build. OK so yes, I needed to build it because it came as a kit.

I’ve been kicking around the idea of getting a laser cutter / engraver for a while and was initially considering one of the ubiquitous K40 Chinese 40W CO2 lasers but there’s a lot which can go wrong with them and I want to be able to use some ‘proper’ software like Lightburn which the K40s don’t support without some significant upgrade work.

So after trolling around for a while I reckoned that the Sculpfun S9 would be the right tool for the job, decent power, Lightburn compatible and a big enough foot print to let me cut and carve EVA foam – which is my primary reason for getting it. I’m happy to do a lot of EVA cutting with a knife, but there have been occasions where I want some fine detailed shapes or to get some surface patterning.

The S9 Kit comes in the usual direct-from-China packaging but the instructions a really clear and the kit includes step-by-step bags of screws and the tools needed to put everything together.

From opening the box to getting the las scre in and powering up took me about 15 minutes. OK, so I’ve built a few 3D printers so I know what bits go where, but even from a cold start this is a kit anyone could build!

I’d also ordered the air-assist kit for the S9 which also came with easy-to-follow instructions and I had an air-pump in my kit which fit the job nicely. I’ll probably replace the air hose itself and the one which came with the kit is a bit stiff and holds onto the kinks so it’ll get swapped for a nice silicon hose instead.

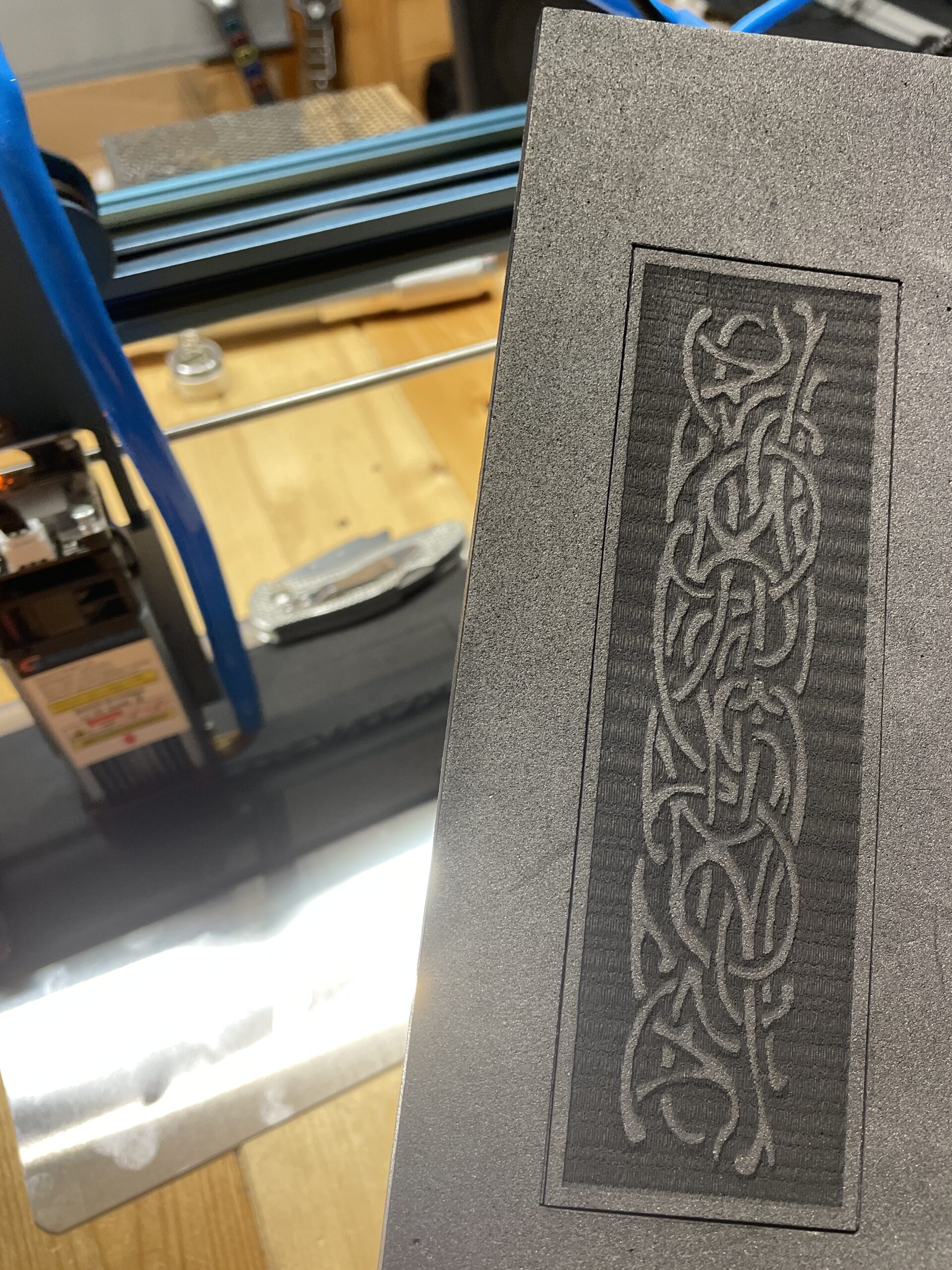

So when the S9 powered up I got Lightburn connected and loaded up a test job. It’s an example of the engraving on the corners of Mjolnir and I thought it’s give me a decent idea of what we can expect to see.

It looks pretty good!

There’s some tuning to be done and I’ve started some material testing to get the right combination of speeds and power levels.